E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

What Is the Difference Between Precision Casting and Ordinary Casting?

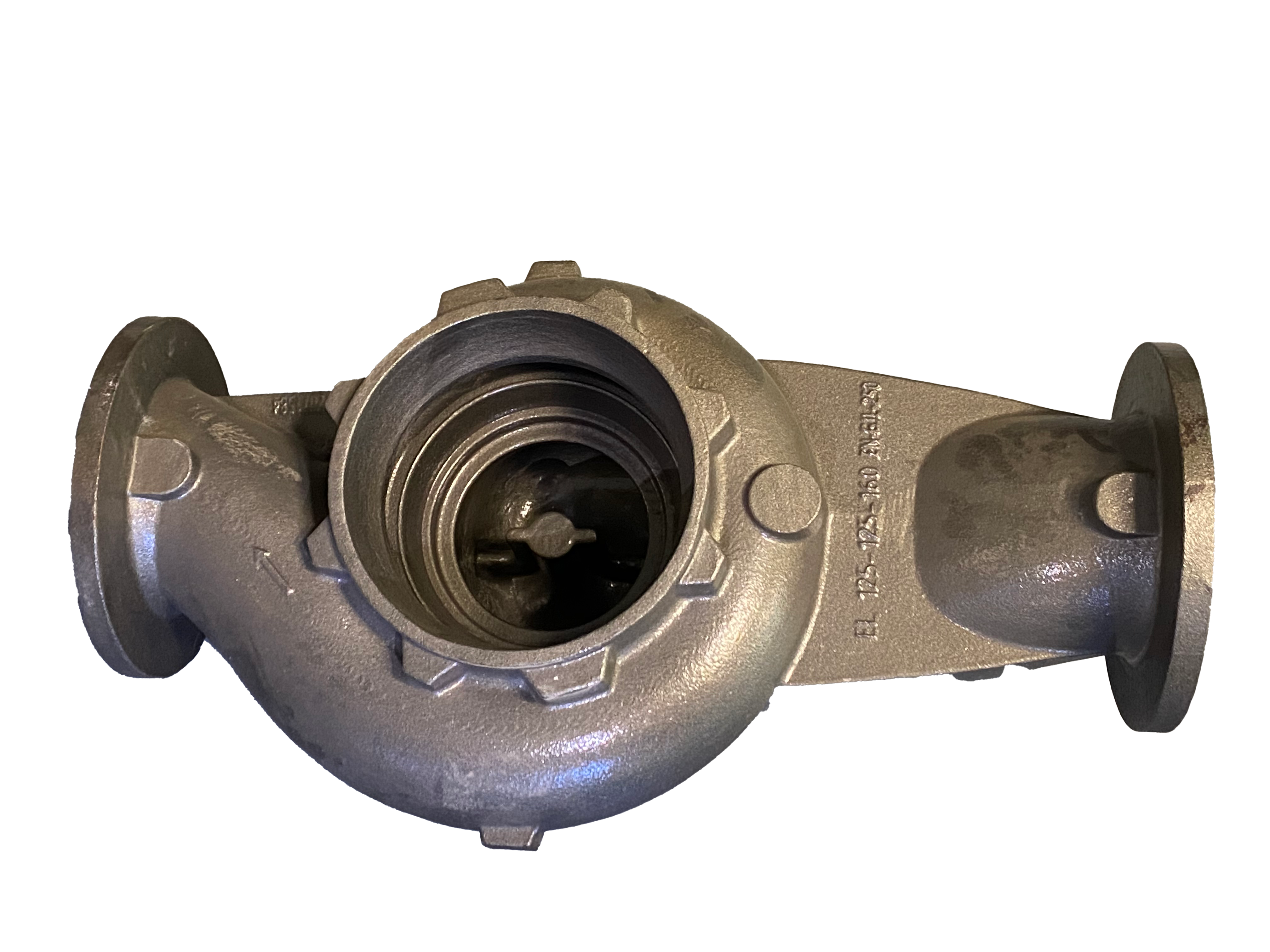

What is the difference between precision casting and ordinary casting? Precision casting belongs to special casting. Compared with ordinary casting, the castings of precision casting can be used without post-processing or only a small amount of processing. Ordinary casting is boring for forging, and die casting is a casting method using pressure casting. It fills the casting mold with liquid metal at a high speed under high pressure. The ordinary casting is more troublesome, and the castings cast by the ordinary casting method still need to be finished after the later stage before they can be put into use.

What is the difference between precision casting and ordinary casting?

- Precision casting is to pour the water of liquid metal into the casting model with the same shape as the part. After the casting is cooled, our precision casting products can be formed. Casting methods include sand casting, special casting, precision casting, V method casting, and precision casting belongs to special casting. Parts cast in this way do not require machining, or require a small amount of machining to be used;

- Ordinary casting is boring, and die casting is a casting method using pressure casting. Liquid metal is filled into the casting mold at a high velocity under high pressure. Let it solidify under pressure. Ordinary casting uses more raw materials and external forces to deform in the solidified state;

In general, precision casting and ordinary casting are two different casting methods, but precision casting has higher requirements and better precision.

What are the main applications of aluminum alloy precision casting?

What are the main applications of aluminum alloy precision casting? Precision casting skills have been developed for 50 or 60 years, and many high-quality, high-efficiency, energy-saving, precision forging skills, hot precision forging, temperature forging, cold-temperature composite molding, composite casting, precision roll forging die forging composite molding has developed rapidly, more and more. The more it is used in the production of automobile transmissions and engine gears, it is widely used in the automobile industry.

With the development of the manufacturing industry, the application of precision casting skills has become more and more extensive, and the requirements for skills have become higher and higher.

✔️The main development directions of aluminum alloy precision casting are as follows:

- The computer imitates the casting process of skills;

- The casting process is developing towards automation and flexibility;

- Green casting molding technology;

✔️The main application of aluminum alloy precision casting:

- Produce refined blanks, and finish precision die forgings to obtain product parts;

- The production of precision die forging parts and precision forging parts saves the need for cutting, while some parts still need a small amount of cutting;

Conclusion

In general, investment casting is also called lost wax casting. Its products are precise, complex, and close to the final shape of the part, and can be used directly without processing or with little processing. Therefore, investment casting is an advanced process with near-net-shape forming.

For more information about lost wax casting materials,lost wax brass casting lost wax casting aluminum, we are glad to answer for you.