E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

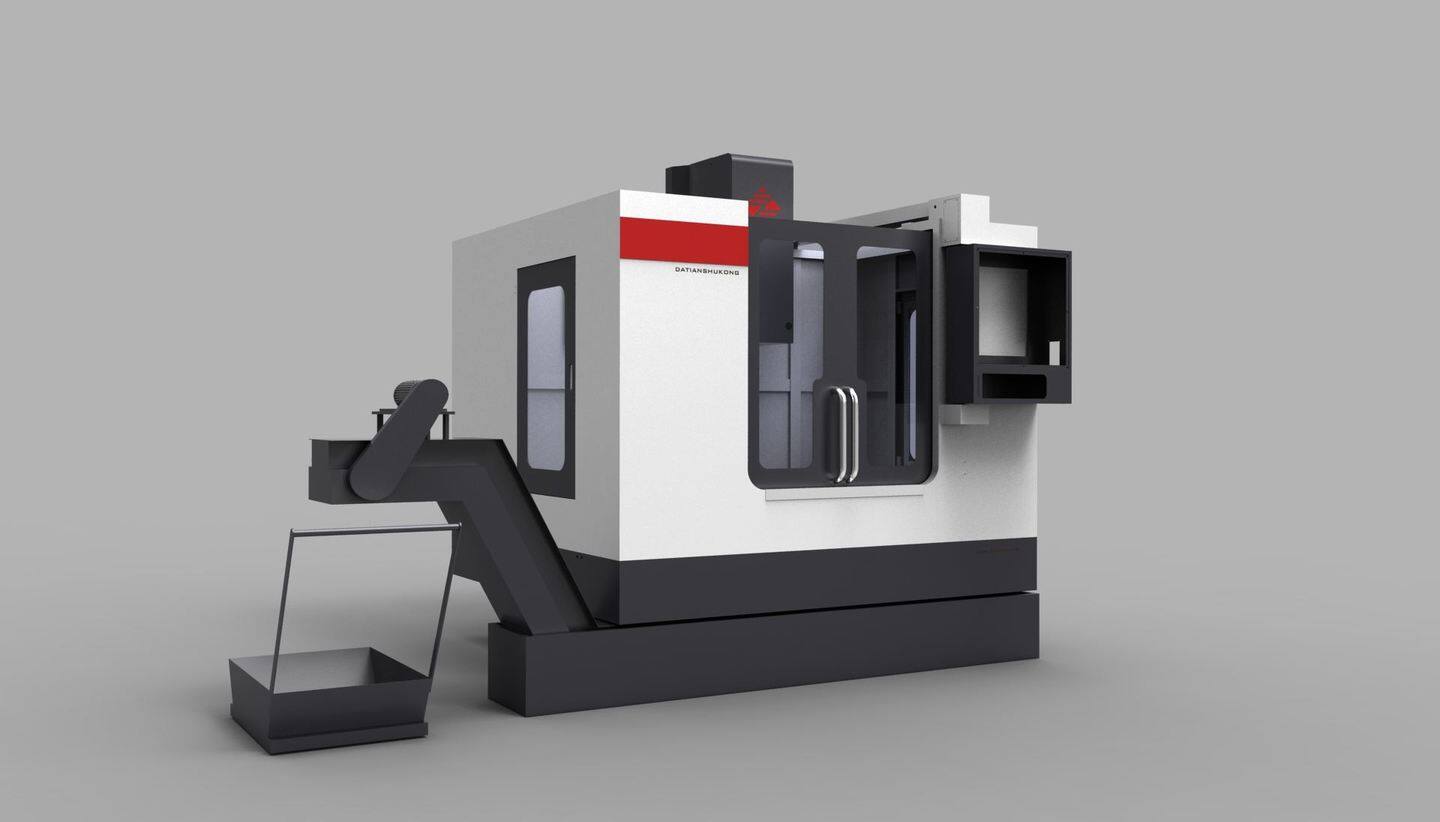

Use, Maintenance and Service of Imported CNC Milling Machine

Requirements for operation and maintenance personnel

The CNC milling machine integrates mechanical, electrical, hydraulic and pneumatic, so the maintenance personnel should not only have knowledge of mechanical, electrical, processing technology, hydraulic, and pneumatic but also understand electronic computer, automatic control, drive, and measurement technology, to fully understand and master the equipment and do a good job of maintenance and repair in time. Before maintenance, read the equipment manual carefully to understand the structure and characteristics of the machine tool, the working principle of the ladder diagram and CNC system, as well as the wiring diagram, etc. The operator must be trained and take the post with a certificate after passing the examination.

Equipment maintenance requirements

- parts and requirements to be inspected every day. The inspection includes whether the oil in the guide rail lubrication station is sufficient and whether the lubrication pump operates normally The guide rail surface shall have visible lubricating oil; The compressed air pressure shall be within the specified range, and the water in the oil-water separator shall be removed, the cooling fan of the electric cabinet shall work normally, and the air duct filter screen shall not be blocked; Guide rail and protective cover shall be free of looseness and water leakage; The hydraulic system has no abnormal sound, the pressure indication is normal, and the oil level of the hydraulic tank is appropriate; there is no abnormal sound when the spindle and X, y and Z coordinates are running; The cutting work can be started only after the machine tool has been operated without load for 10 minutes.

- annual maintenance requirements. Clean the bottom of each lubricating oil pool and the bottom of the oil tank of the hydraulic station, clean or replace the oil filter, and replace or filter the lubricating oil and hydraulic oil. Check and adjust the geometric accuracy of the CNC milling machine.

- irregular maintenance and servicing requirements. Check and adjust the guide rail insert and pressing wheel, check and clean the chip conveyor, and clean the waste oil pool and cutting fluid tank.

Matters related to installation, use, and maintenance

- the installation method depends on the processing object. When processing small parts, as long as the ground is firm and the endurance is above 5t/m', they can be directly installed and equipped with an adjustable inclined sizing block. However, if there are earthquake sources around, shockproof ditches must be made.

- do not use compressed air to clean the machine or other components, because dust and metal powder will blow into the bearing or slide.

- the abnormal sound of the main shaft is generally caused by bearing damage or wear, which needs to be replaced. As it is a high-precision angular ball bearing, pay attention to the installation direction when installing.

- always pay attention to the working condition of the backup battery, because the system parameters and processing programs are saved by the static register with power-down protection, and the contents in the memory are maintained by the backup battery after the system is shut down. If the battery voltage alarm occurs after the system is started, the battery shall be replaced immediately. In order not to lose parameters and procedures, it is necessary to replace them when the system is started. Generally, the battery life is two years.

- if the CNC system is idle for a long time, it should be powered on frequently to make the system run idle when the machine tool is locked. After the system is powered on, the heat emitted by the electrical components can disperse the moisture in the CNC cabinet and ensure the stable and reliable performance of the electronic components. The practice has proved that in areas with high air humidity, frequent power is one of the effective measures to reduce faults.

- various fuses, brushes, transistor modules, and printed circuit boards that are prone to failure shall be properly reserved. Spare parts that are not easy to damage, such as CPU modules, register modules, and display systems, need not be reserved because of their high prices to avoid overstocking of funds. The spare printed circuit board shall be regularly installed on the CNC system for the power-on operation to avoid long-term failure.

Summary

The above use, maintenance, overhaul, and troubleshooting are only a common part. Due to the high technical content and various forms of CNC milling machines, different manufacturers have different characteristics, which requires users to refer to the general theory, combined it with the actual situation, and fully understand the operation manual, to do a good job in the use, maintenance and repair of the equipment, avoid accidents, and meet the production needs.

Searching for a bantam cnc milling machine, cnc milling machine controller, cnc milling machine aluminum manufacturer from China, you can get high-quality products at a nice price.