E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

The Reason Why Die Casting Is Easy to Blacken And Darken

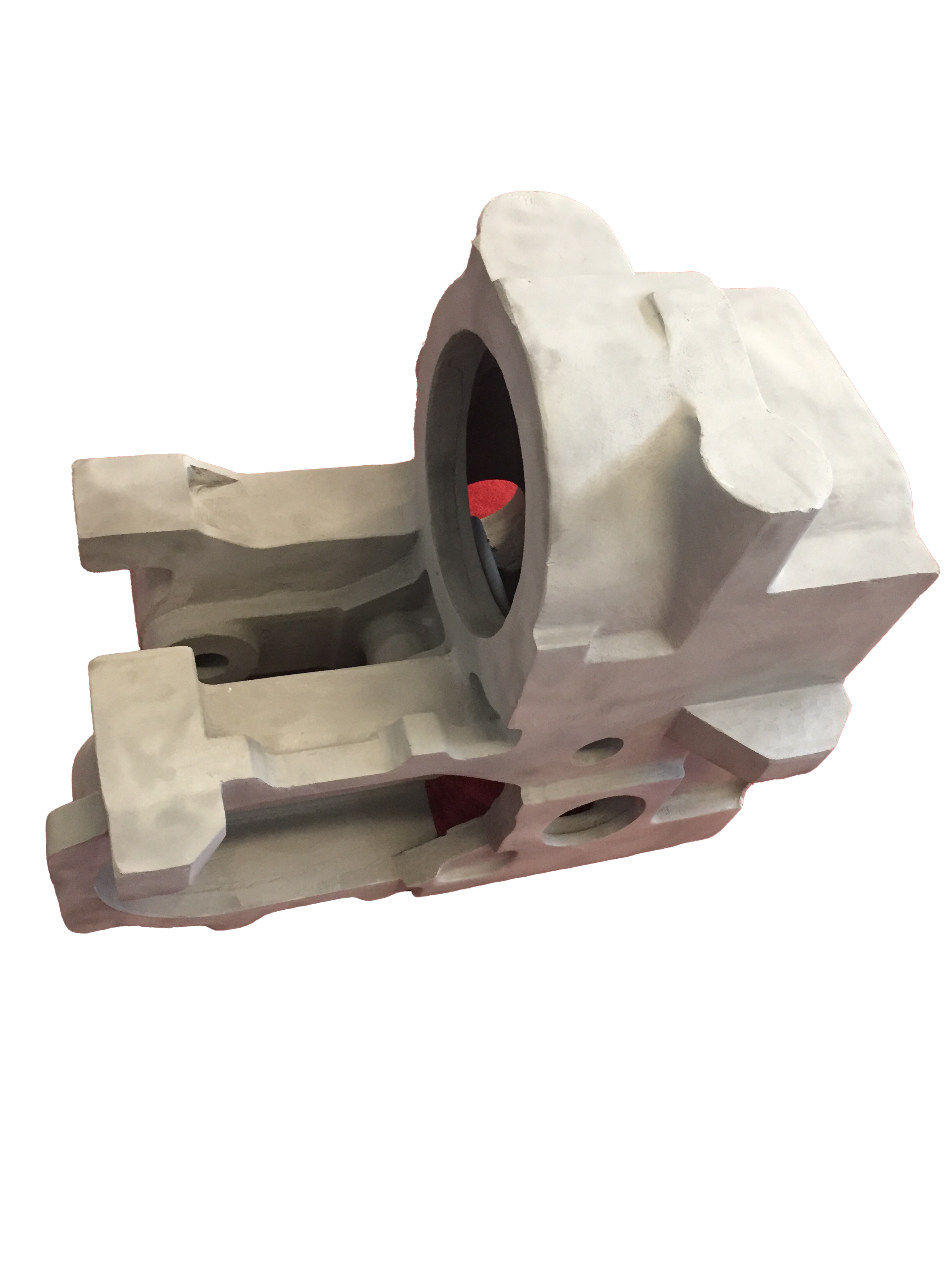

Aluminum oxidation treatment production and processing aluminum casting is generally all with metal type casting, metal aluminum and aluminum alloy profiles with very good circulation and ductility, but in the application of the whole process of aluminum alloy die casting very easy to black, what is going on?

Why die casting is easy to blacken and darken

- Process technology is not scientific. Aluminum alloy casting parts in the cleanup or pressure check after negligence, for aluminum alloy casting parts long mold blackening created the standard, accelerate the transformation of mold into.

- Logistics and storage management is not timely. The aluminum alloy casting parts stored in the warehouse is not the same height to width ratio, and its long moldy situation is not the same.

- The internal elements of aluminum alloy profiles. Many aluminum alloy profile die casting manufacturers in aluminum die-casting, mechanical processing process later, do not do all clean-up solutions, or simple tap water filling, can not ensure complete clean-up neat, die-casting aluminum surface residue of corrosive chemicals such as stripping agent, cutting oil, soap foot liquid and other dirt, this dirt accelerates the rate of aluminum alloy casting parts long mold spot blackening.

- Aluminum alloy profile environmental factors factors. Aluminum is an active metal, in a certain temperature and environmental humidity standards very easy to air oxidation blackening or long mold, it is the characteristics of aluminum itself decision-making.

- The use of cleaning agents can not be when. The use of cleaning agents with strong corrosion, resulting in die-casting aluminum leaching air oxidation.

Die casting processing process

Casting parts production processing must which the production process

- Professional skills department (production line) according to the production and manufacture of necessary methods of machining parts preparation reported to the senior engineer for review.

- Professional skills department according to the machine processing parts preparation method material preparation, program chart, professional skills limit and comprehensive working hours carry over reported to the senior engineer audit; material preparation by the Ministry of presentation to implement the acquisition; audit program chart, professional skills limit and comprehensive working hours and orders by the production technology department structure and amicable production and processing.

- Internal production processing and outsourcing processing

Internal production processing.

- The Department of Professional Skills submits the audited engineering drawings, professional skills limits and comprehensive working hours and orders to the Department of Production Technology according to the preparation of production and processing.

- After receiving the engineering drawings, limits, comprehensive working hours and orders submitted, the Production Technology Department will immediately discuss with the railroad switch to clarify whether it is able to produce and process.

- Clearly capable of production and processing by the production workshop structure of railroad turnout production and processing.

Outsourcing processing.

- Railroad turnout is not good to production processing by the Ministry of professional skills placement outsourcing processing.

- Based on the outsourcing enterprise mechanical processing ability and production processing cost (compare with the best price), clear production processing enterprise, sign the production processing unequal treaty and report to the senior engineer for review.

- Outsourcing enterprises according to the program map, professional skills limit structure production and processing.

- Internal production and processing and outsourcing processing, production and processing of finished products to the material depot to apply for incoming procedures; material depot care quality inspection positive intermediate inspection.

- Quality inspection is in the middle of the inspection to meet the standard after presenting the standard certificate.

- Professional skills department according to the standard voucher combing orders reported to the senior engineer assessment, assessment of accurate reported to the manager agreed to the financial department to hold settlement business.

Casting parts production and processing has a strict production process, the workers should pay attention to the actual operation, to prevent excess incorrect and cause safety accidents.

Conclusion

If you are looking for a cost of die casting machine,material used in preparation of die casting mould,die casting components manufacturers, we hope we will be your best choice.