E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

How much do You Know about Grey Cast Iron?

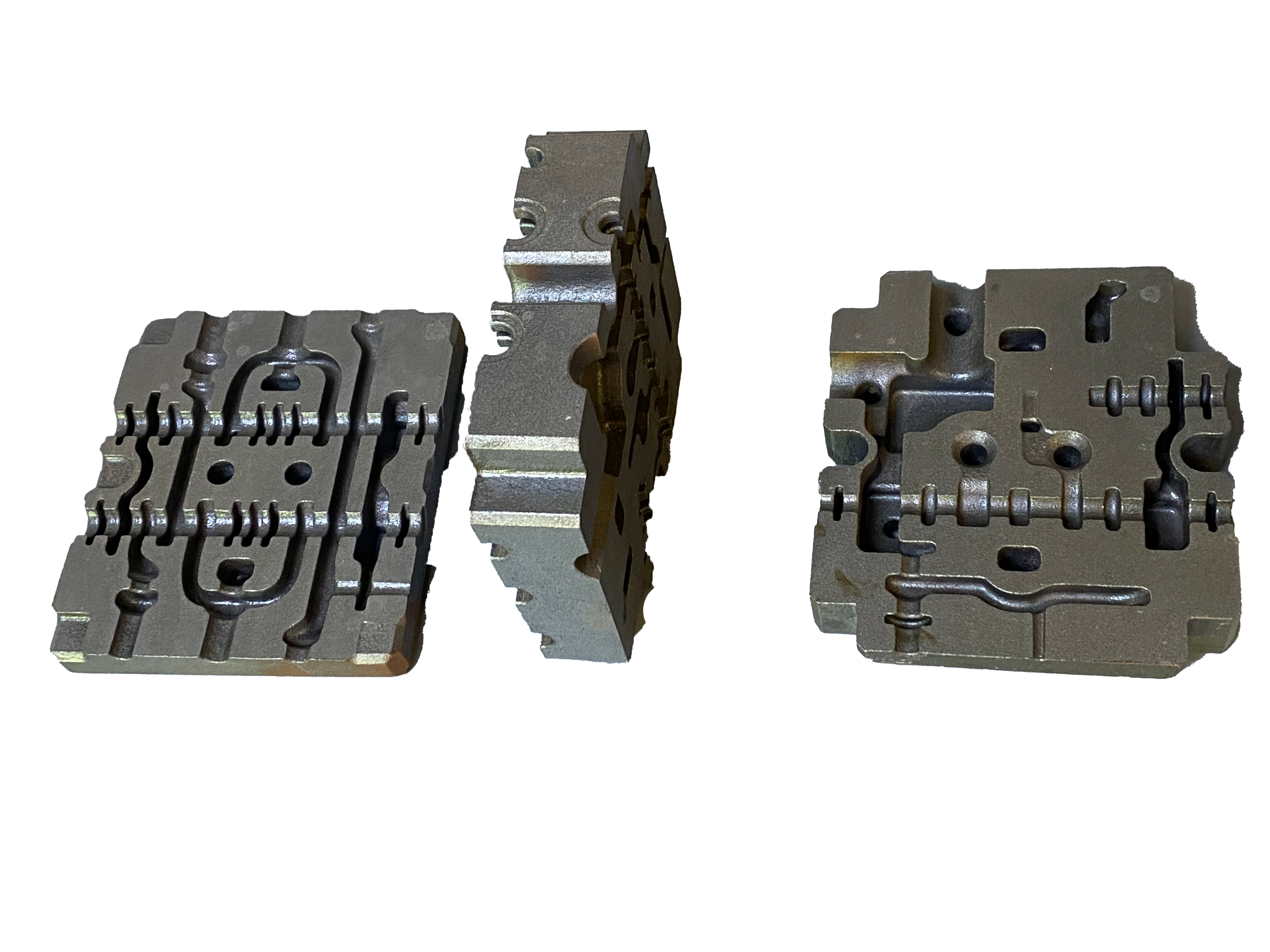

Gray cast iron is a kind of cast iron with gray section and carbon mainly in the form of flake graphite. It is the most widely used cast iron. The castability, machinability, wear resistance and shock absorption of gray cast iron are better than other kinds of cast iron, and the production is convenient, the product rate is high and the cost is low. Therefore, cast iron has been widely used in industrial and agricultural production, accounting for more than 80% of the total output of all kinds of cast iron.

Grade, chemical composition, and anti-microstructure of grey cast iron

According to the national standard GB, 9439-88 for the classification of hair cast iron, the grades of gray cast iron in China are divided into six grades.

"HT" refers to the first capital letter of the Chinese phonetic alphabet of gray iron, and the numbers after it represent the tensile strength. See the table for the chemical composition of cast iron.

The microstructure of gray cast iron is composed of flake graphite and metal matrix. The degree of graphitization in the eutectoid phase of the metal matrix can be divided into ferrite, ferrite pearlite, and pearlite.

The metal matrix of common gray cast iron is mainly pearlescent and contains a small amount of ferrite; High strength cast iron is mainly pearlite as a matrix, and high silicon cast iron is mainly a ferrite matrix.

Properties and applications of grey cast iron

The properties of grey cast iron are closely related to other chemical compositions and structures.

- excellent casting performance

Because the chemical composition of your cast iron is close to the eutectic point, the molten iron has good fluidity and can cast very complex parts. In addition, due to the large specific volume of graphite, the shrinkage of the casting during solidification is reduced, which can simplify the process, reduce the stress of the casting and obtain a dense structure.

- Excellent wear resistance and shock absorption

Graphite itself has the function of lubrication. The cavity after falling graphite can absorb and store lubricating oil so that the castings have good wear resistance. In addition, due to the high hardness of phosphorus eutectic in the casting, the anti-wear ability can be further improved, which is of great significance for the preparation of piston rings, cylinder liners, and other friction parts.

Graphite can prevent the propagation of backward movement. The anti-exaggeration ability of gray cast iron is 10 times that of steel. It is often used to make machine tool bases that bear vibration.

- low notch sensitivity and good machinability

Due to the existence of graphite in gray cast iron, the surface defects and notches are almost insensitive when there are many small notches. Therefore, the surface defects have little effect on the fatigue strength of cast iron, but their fatigue strength is lower than that of steel. Because the graphite in the cast iron can play the role of chip breaking and obstacle reduction for the lubrication of cutting tools, its machinability is excellent.

- mechanical properties of grey cast iron

The tensile strength, plasticity, toughness, and elastic modulus of cast iron are lower than those of carbon rust steel, as shown in the table. The compressive strength and hardness of gray cast iron mainly depend on the matrix structure. The compressive strength of grey cast iron is generally three or four times higher than the tensile strength, which is a characteristic of grey cast iron. Therefore, it is better to make pressure parts than to use gray cast iron as tensile parts. This is why it is widely used as a pressure-resistant part of machine tool bed and support.

Searching for a large cast iron, philippe richard cast iron, cast iron use manufacturer from China, you can get high-quality products at a nice price.