E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

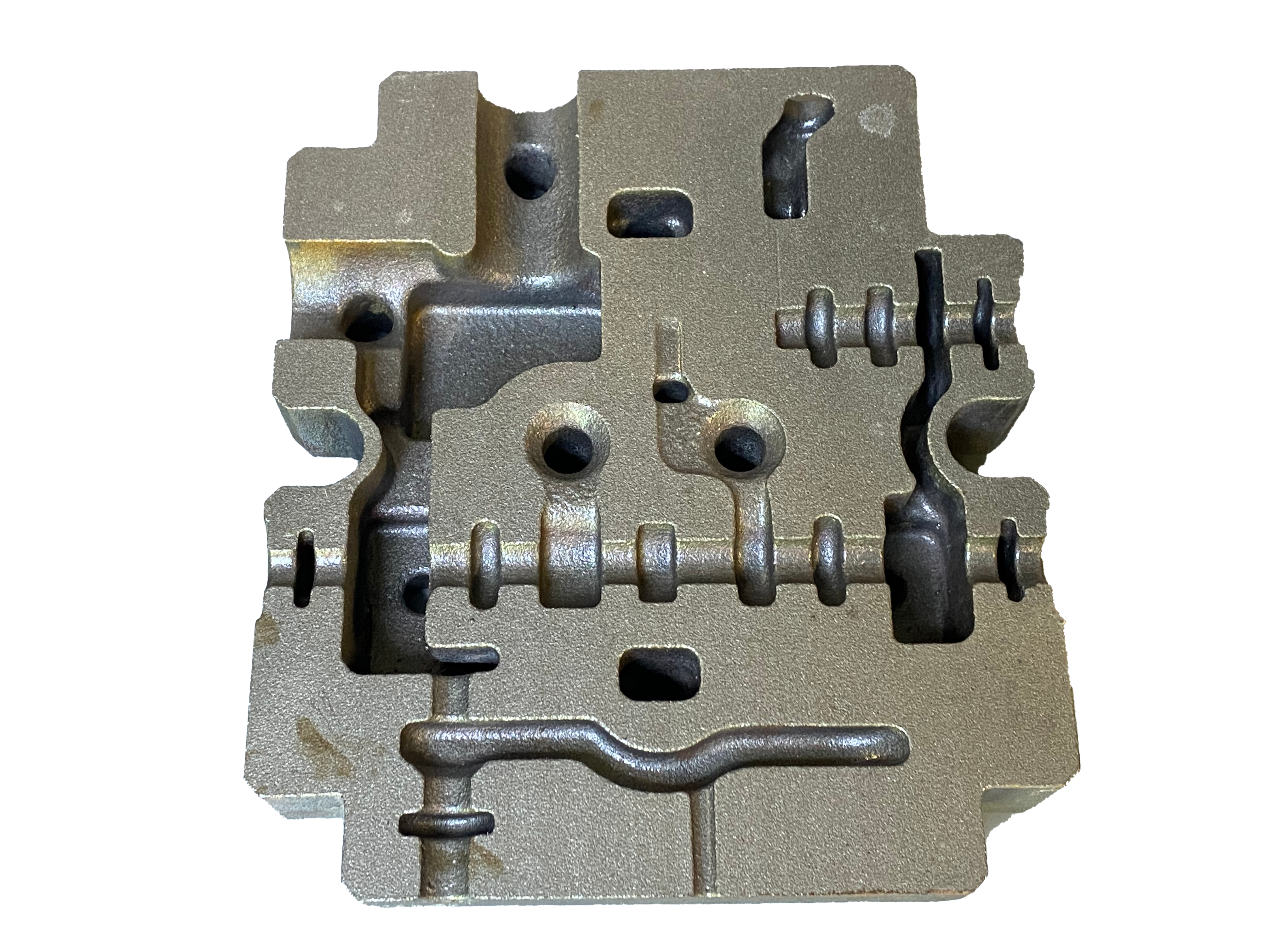

Do You Know Cast Iron Welding?

Cast iron has high carbon content and poor weldability and is rarely used in welding structures. The so-called cast iron welding mainly refers to the welding of casting defects and damaged castings.

- It is easy to produce thermal stress cracks

Heating, cooling, and unreasonable preheating in the welding process will make the weldment unable to expand and contract evenly and produce thermal stress. When the tensile strain caused by thermal stress exceeds the deformation capacity of a weak part of the material, cracks will appear, which are thermal stress cracks. The manifestations of thermal stress cracks are:

- In the process of heating up or cooling after welding, the base metal outside the repair welding area breaks, and its position occurs at the weak section and the sudden change of section shape or wall thickness of the cast iron, which is caused by improper local preheating or excessive welding heating specifications.

- During the cooling process, transverse lines are produced in the weld or repair welding area, and the direction is perpendicular to the fusion line. Sometimes this kind of weld only occurs on the base metal adjacent to the weld, some are connected with the weld heat lines, and some are transverse to the weld and the adjacent base metal. The reason is caused by unreasonable operation processes, especially the long primary weld or improper heating.

- During the cooling process, the weld metal produces cracks along the fusion line (sometimes the weld and the base metal peel off). This kind of striation mostly occurs in the welding process of non cast iron electrodes. The higher the strength of the welding material or the lower the strength of the cast iron base metal, the greater the tendency of this kind of crack, and the more filler metal, the easier it is to peel off. Therefore, during welding, it is necessary to appropriately increase the overall welding environment temperature of the weldment, control the temperature of the repair welding area, and adopt short weld bead intermittent welding, At the same time, the weld shall be hammered timely and fully after the welding, to avoid the occurrence of thermal stress cracks.

- The fusion zone is easy to produce a white mouth structure

When using cast iron as the filler metal pair, we must slow down the cooling rate at high temperatures (above 800 ℃) and increase the content of carbon and silicon to improve the graphitization ability of welding, which can reduce and prevent the white structure in the weld metal and fusion area. When using high nickel or pure nickel electrodes for welding, we can also reduce the white tendency in the fusion area.

- Hot streak tendency of welding metal

When using a noncast iron structured electrode or welding wire to cold weld cast iron, the hot crack of the weld varies according to the material of the weld. Increasing the fusion ratio of the base metal in the weld and excessively prolonging the residence time of the weld at high temperatures will increase the hot crack tendency. Corresponding welding processes can be adopted, such as slippery grooves, small currents, short and narrow weld beads, and intermittent welding, which can reduce the hot crack tendency.

Make a purchase of cast iron induction, cast iron sale, ductile cast iron from China, you can get them at a good price if you have a large quantity. We hope to be your long-term partner.