E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nyheter

custom aluminum die casting,aluminium die casting supplier,aluminium casting suppliers

Aluminum alloy is the earliest casting metal discovered and used by mankind. It is characterized by high electrical and thermal conductivity and good plasticity. Its commonly used casting alloys include aluminum-zinc alloys, aluminum-copper alloys, aluminum-magnesium alloys, and aluminum-silicon alloys.

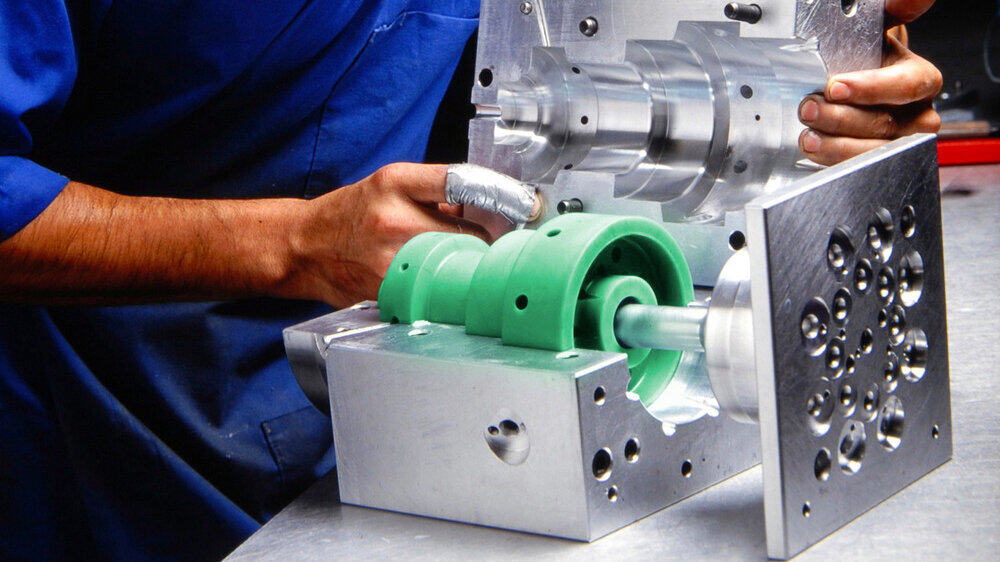

The aluminum alloy die-casting process uses high pressure to press the molten metal into the cavity of the precision metal mold at a high speed, and the molten metal cools and solidifies under the action of pressure to form aluminum alloy die-casting.

Aluminum alloy die casting is the most widely used die casting material at present. Aluminum alloy die-casting products are mainly used in lamps, automobiles, motors, home appliances and some communication industries. Some high-quality aluminum alloy products with high performance, high precision and high toughness are also used in large aircraft, ships and other industries with high requirements. Its main use is still on the parts of some instruments.

The main features of aluminum alloy die castings are as follows:

- The density is small and the specific strength is high.

- It has good mechanical properties at both high temperature and normal temperature, especially the impact toughness is particularly good.

- It has good electrical and thermal conductivity. Machining performance is also very good.

- There is a chemically stable and dense aluminum oxide film on the surface, so most aluminum alloys have good corrosion resistance in fresh water, sea water, nitrate and various organic substances. But this layer of aluminum oxide film can be destroyed by chloride ions and alkali ions.

- It has good die casting performance and good surface roughness.

Advantages of aluminum alloy die castings

- High production efficiency. Due to the fast filling speed and short filling time, the metal industry solidifies rapidly, and the cycle speed of die casting operation is fast. Among various casting processes, die casting has the highest productivity and is suitable for mass production.

- Easy-to-use inserts. The positioning mechanism is easy to install on the die-casting mold, which is convenient for inserting the insert, and meets the local special performance requirements of the die-casting part.

- It can manufacture metal parts with complex shape, clear outline, thin wall and deep cavity. Because y molten metal maintains high fluidity under high pressure and high speed, it can obtain metal parts that are difficult to process by other processes.

- The utilization rate of materials is high. Due to the high precision of die-casting parts, it can be assembled and used only after a small amount of machining, and some die-casting parts can be directly assembled and used.

The future development of aluminum alloy die castings

As one of leading aluminium casting suppliers, we summarized as below:

As a non-ferrous metal material, cast aluminum alloy is not inferior to steel material in rigidity, plasticity and strength, and is widely used in aerospace, automobile manufacturing and other industries due to its advantages of light weight and high output.

In the automobile manufacturing industry, the comfort, operability and energy consumption of a car are all the criteria for consumers to choose a car. When advocating energy conservation and emission reduction, automobile manufacturing is faced with breakthroughs and changes: one is to change the internal structure, and the other is to develop lightweight vehicles.

The former has been almost perfected in automobile manufacturing, and the latter is a new development path to seek better development. As a lightweight material, aluminum alloy has always been widely concerned. How to make aluminum alloy better used in automobile manufacturing and even more machinery manufacturing industries has become an eternal research topic for technical workers.

In the end

After reading the above content, if you have a comprehensive understanding about custom aluminum die casting. If you are looking for a aluminium die casting supplier, we hope we are your best choice. Any interests in die casting parts, please feel free to contact us at any time.